No downstream heat treatment, CO2 savings for customers

GMH Gruppe Green Steel

Decarbonisation pioneer in the steel industry: With Green Steel, we’re one step ahead when it comes to sustainability.

Future-oriented solutions

GMH Gruppe Green Steel makes our customers’ products more sustainable – thanks to climate-friendly production processes, even today:

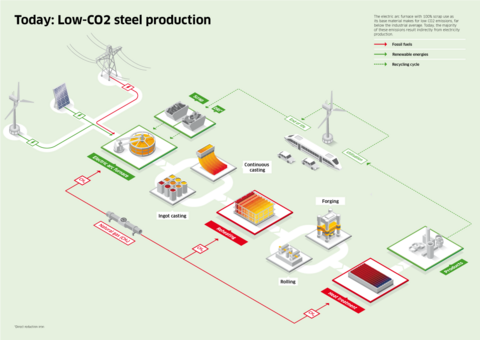

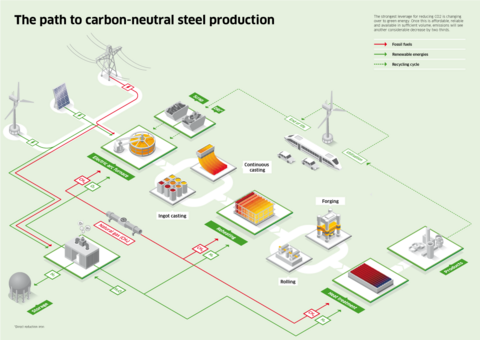

Each tonne of crude steel from our electric arc furnace causes 80 % less CO2 emissions than comparable steel from integrated steelmaking routes. We use 100 % scrap as feedstock. Our value stream saves emissions thanks to climate-friendly logistics. New sustainable measures and innovative products are constantly being added. Above all: We have a clear, realistic roadmap for how we will produce our already low-emission steel in a completely climate-neutral way by 2039.

Measures: We are always improving

- We use the growing infrastructure for green electricity and hydrogen in Europe

- We are further expanding our recycling of mineral secondary materials

- We are continuously working on reducing our energy requirements

- We regularly have our energy management system externally certified according to ISO 50001

- We actively involve employees, e.g. through our company suggestion scheme and training courses at the GMH Akademie.

- We have established a sustainability management system connected to management as an executive department which, together with other management systems, coordinates all sustainability issues

- We develop steels that enable leaner processes in further processing, which reduces emissions MORE INFORMATION →

- Our steels also save emissions during their use MORE INFORMATION →

- We rely on state-of-the-art technologies that clearly go beyond the legal requirements MORE INFORMATION →

- We use our waste heat for our processes and feed it into district heating networks MORE INFORMATION →

GREEN STEEL innovations

Conrods made from 46MnVS5

10% lighter than C70S6, for efficient, lightweight construction (reduces vehicle emissions)

Tangible sustainability: Our products

Learn more about our sustainability strategy – get in touch with us.

Contact

Luciana Filizzola

Director Sustainability and Communications- Phone: +49 160 95222954

- Email: Luciana.Filizzola@gmh-gruppe.de