Crankshafts

With decades of experience in mechanical processing, GMH Gruppe is a specialist in large crankshafts for shipbuilding, large stationary engines and pumps as well as compressors. We also offer eccentric shafts for a wide range of applications.

We produce our crankshafts and eccentric shafts from steel melting, through the forging process and mechanical processing to the ready-to-install product. Optimum steel properties and precisely coordinated processes with high-performance machines guarantee results of the highest quality and dimensional accuracy. We also offer after-sales services for crankshafts, including damage and wear assessments and repairs.

Specifications

Crankshafts

Application examples

Crankshafts for large engines (4-stroke engines), e.g. for locomotives, ships and for stationary power generation power generation

Product

Crankshafts for four-stroke engines

Product

Crankshafts for pumps

Product

Crankshafts for compressors

Product

Camshafts

Product

Shafts made to measure

Your contact

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Andreas Bruntsch

Sales Director Open Die Forgings & Machining

Further processing possibilities

Mechanical processing options

Milling

Turning

Turning-milling

Drilling

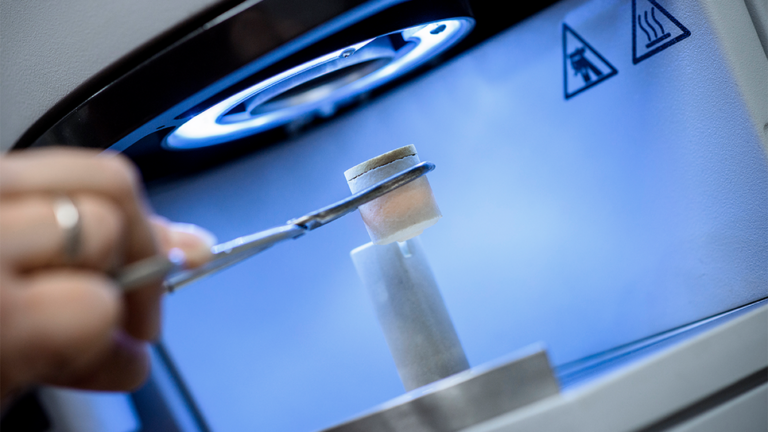

Grinding

Material Testing

US testing

Magnetic crack detection

Determination of chemical analysis

Compression, tensile and notch impact testing

Microstructure check

Hardness testing according to HV, HB, HRc

Automatic dimensional inspection

Phased-array

What you can expect

Raw material recycling

We use almost 100 % scrap in steel production for our open-die forged products, thereby enabling closed cycles

Wide range

Various machining options for crankshafts

Great variety

We can offer a wide range of material grades for crankshafts

Related products

Contract manufacturing

Open-die forgings

Our innovations

Find out more about the future of steel and the exciting developments that are shaping our world.