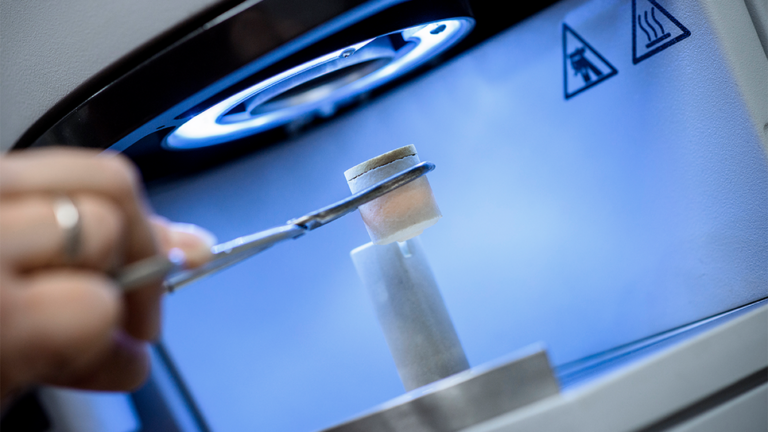

CNC components

We offer our steel as CNC-machined components. Thanks to our high-performance machinery, we are able to produce complex shapes exactly as required.

We use high-quality primary material, e.g. from our own production, to machine our CNC components. High-performance CNC systems such as our double or single-spindle system with 9-axis control can produce almost any contour. We use them to produce a wide range of complex CNC components and ready-to-install parts, with a high-quality coating if required.

Specifications

CNC components

Application examples

Components for hydraulic systems in lifting masts, CNC-machined weld-in bushes, components in the drive train of passenger cars

Contact

We manufacture all our products to customer specifications.

Please feel free to contact us. Together we will find your perfectly customized solution.

Mario Griesmaier

Senior Sales Manager Piston and connecting rods & CNC components

Further processing possibilities

Heat treatment

Treated to hardness range

(+TH)

Quenching and tempering

(+QT)

Treated to ferrite-pearlite microstructure and hardness range

(+FP)

Soft-annealing

(+A)

Spheroidising

(+AC)

Stress-relieving annealing

(+SR)

Induction surface hardening

(+IH)

What you can expect

Raw material recycling

We use almost 100 % scrap in our low-CO2-emission steel production, thereby enabling closed loops

Broad product range

Bright steel with added value from a single source, even with smaller batch sizes

Short-term availability

Bright steel of various grades and special analyses

Related products

Bright steel

Cut lengths

Piston rods

Our innovations

Find out more about the future of steel and the exciting developments that are shaping our world.