Stahlwerk Bous: New filter installation

Stahlwerk Bous: New filter installation

State of the art – for our employees and the environment

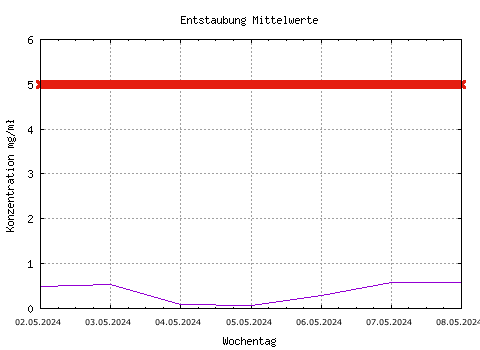

A truly groundbreaking, future-oriented investment - the new dust-extraction system at Stahlwerk Bous GmbH boosts steel production and protects the environment simultaneously. Not only is the exhaust air released by the steelworks now five times cleaner than required by the applicable environmental law - steel output from the Bous AC EAF (electric arc furnace) has also increased significantly since the installation of the new filter system.