Mandrel bars

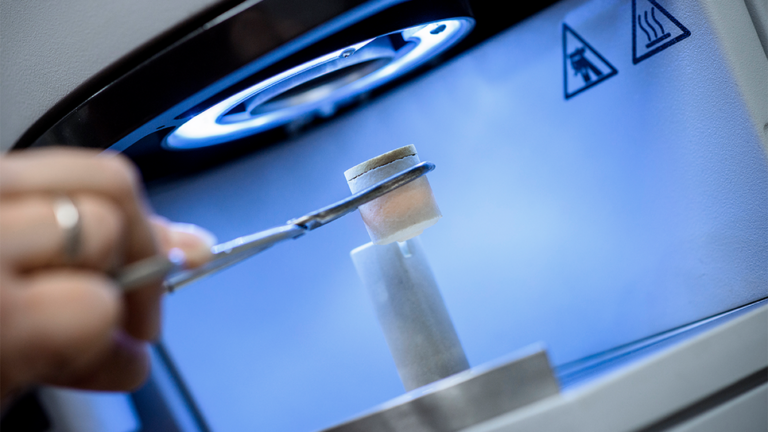

We are a leading manufacturer of mandrel bars, which are used as tools in the production of seamless rolled tubes.

Our mandrel bars are manufactured by rolling or forging, tempered and surface-finished by peeling. Finishing is carried out on CNC lathes. The mandrel bars are then scaled or chrome-plated. In addition to a wide range of designs, we offer close cooperation in the planning and finishing of your equipment as well as complete solutions including the primary material.

Specifications

Mandrel bars

Application examples

Production of seamless rolled tubes, such as for the transportation of hydrogen

Samples from our Portfolio

Material no.

1.2740

Name

28 NiCrMoV 10

Material no.

1.2342

Name

X35CrMoV5-1

Material no.

1.2344

Name

X40 CrMoV5-1

Contact

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Zafer Anil Özer

Senior Sales Manager Mandrel Bars, Peeled Bars & CNC

Further processing possibilities

Mechanical processing options

Grounding

Descaling

Surface treatment

Chromium-plating

Case-hardening

What you can expect

Raw material recycling

We use almost 100% scrap in our low-CO2 steel production, thereby enabling closed loops

High depth of added value

Added value from a single source, even with smaller batch sizes

High-quality product expertise

Supplying well-known tube manufacturers

Our innovations

Find out more about the future of steel and the exciting developments that are shaping our world.