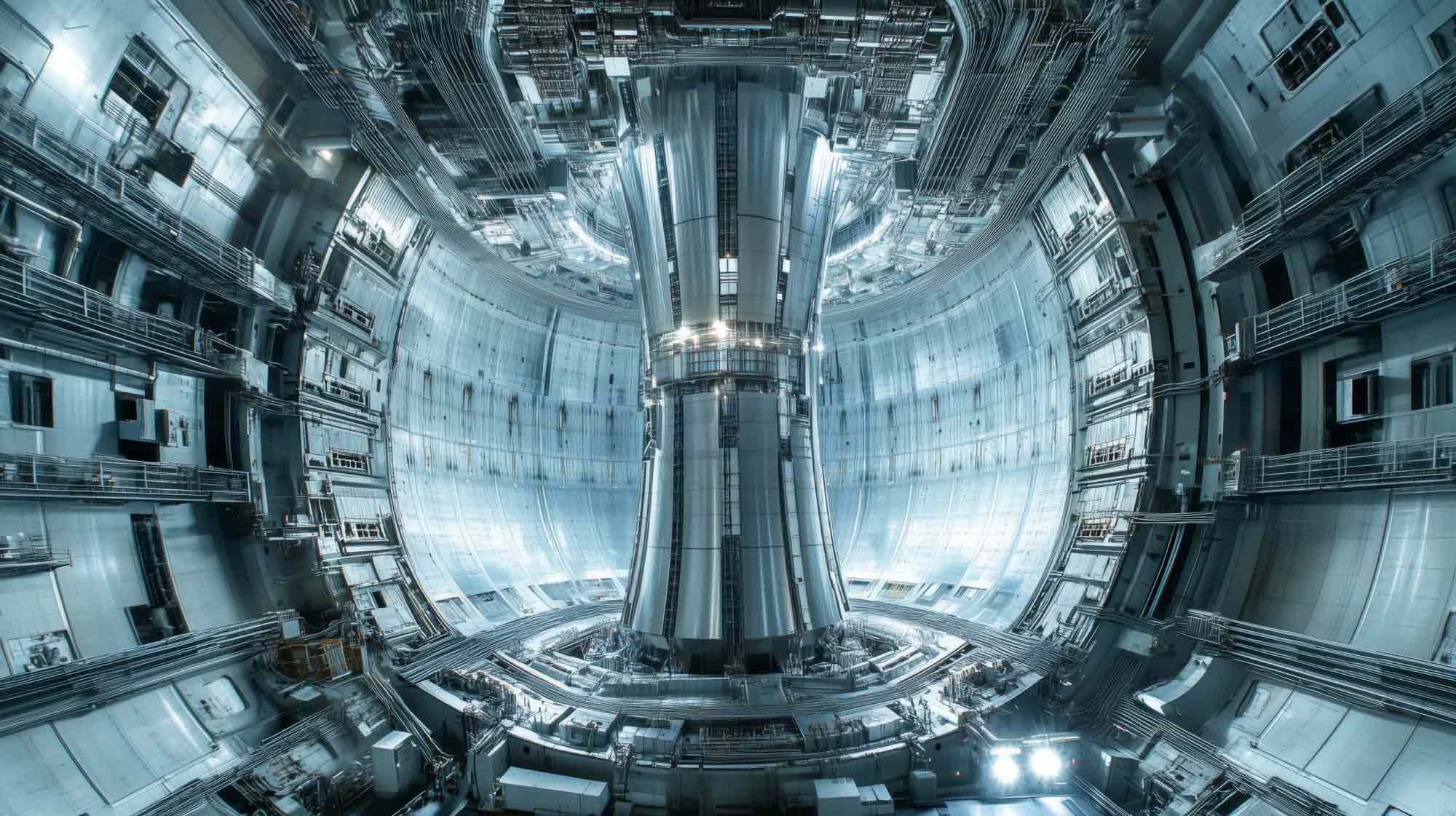

GMH Gruppe Supplies Special Steels for the ITER Fusion Reactor

In the mid-1990s, GMH Gruppe (GMH) began forging the first test components for the international nuclear fusion reactor ITER. As one of the world’s largest and most ambitious energy projects, ITER aims to bring the sun’s energy to Earth. With reactor core temperatures exceeding 150 million degrees Celsius, the project presents immense technical challenges for science and industry. Today, as the reactor is nearing completion, GMH has supplied more than 7,000 tonnes of highly specialized steel for the project – a flagship initiative undertaken in a long-term partnership with Rolf Kind GmbH (Kind).

Innovative Special Steels for the ITER Reactor

Together with its partner Kind & Co, GMH Gruppe’s company Schmiedewerke Gröditz GmbH developed non-magnetisable, high-strength, and oxidation-resistant ESU ingot steels. Engineers crafted bends and crescent-shaped forged components, which are installed in the reactor vessel as vacuum-tight elements, among other applications. These steels withstand extreme forces and had to be processed with the utmost precision to meet stringent safety standards. Schmiedewerke Gröditz GmbH is a leading manufacturer of open-die forgings, tool steel and rolled rings.

Challenges in the Production of Non-Magnetisable Steels

Manufacturing these advanced materials required precision and extensive preliminary technical discussions to assess feasibility. Due to the sensitivity of highly alloyed materials during the forming process, the risk of breakage was a constant challenge. GMH and Kind leveraged their full expertise in forging technology, carefully experimenting with deformation time, material thicknesses and component configurations.

How much deformation was possible on the forging press? Would a certain thickness lead to excessively fast cooling? How much mechanical processing was necessary? From one melt to the next, the team meticulously refined the steel composition, adhering to strict tolerances, continuously improving the results – until they achieved optimum quality.

Sustainable Energy Production through Nuclear Fusion

The ITER project represents the future of sustainable energy production. If the experiments are successful, nuclear fusion could play a crucial role in combating climate change and reducing CO₂ emissions. Through its contributions to ITER, GMH is securing additional orders in related fields and making a significant impact on the transition to a climate-friendly energy future.

ITER: A Project with Global Impact

The ITER reactor has the potential to revolutionize energy production worldwide. This makes GMH Gruppe’s involvement – through its high-performance materials and advanced manufacturing processes – all the more significant.

‘For us as a steel producer, working on this project is truly impressive, especially in the context of today’s global challenge. It aligns with our corporate strategy, and I personally identify with its purpose. It’s a meaningful endeavor that contributes to making the world a better place,’ explains the salesteam of Schmiedewerke Gröditz GmbH.

The close cooperation between science and industry demonstrates how innovative special steels can help address challenges and drive progress toward a more sustainable future.