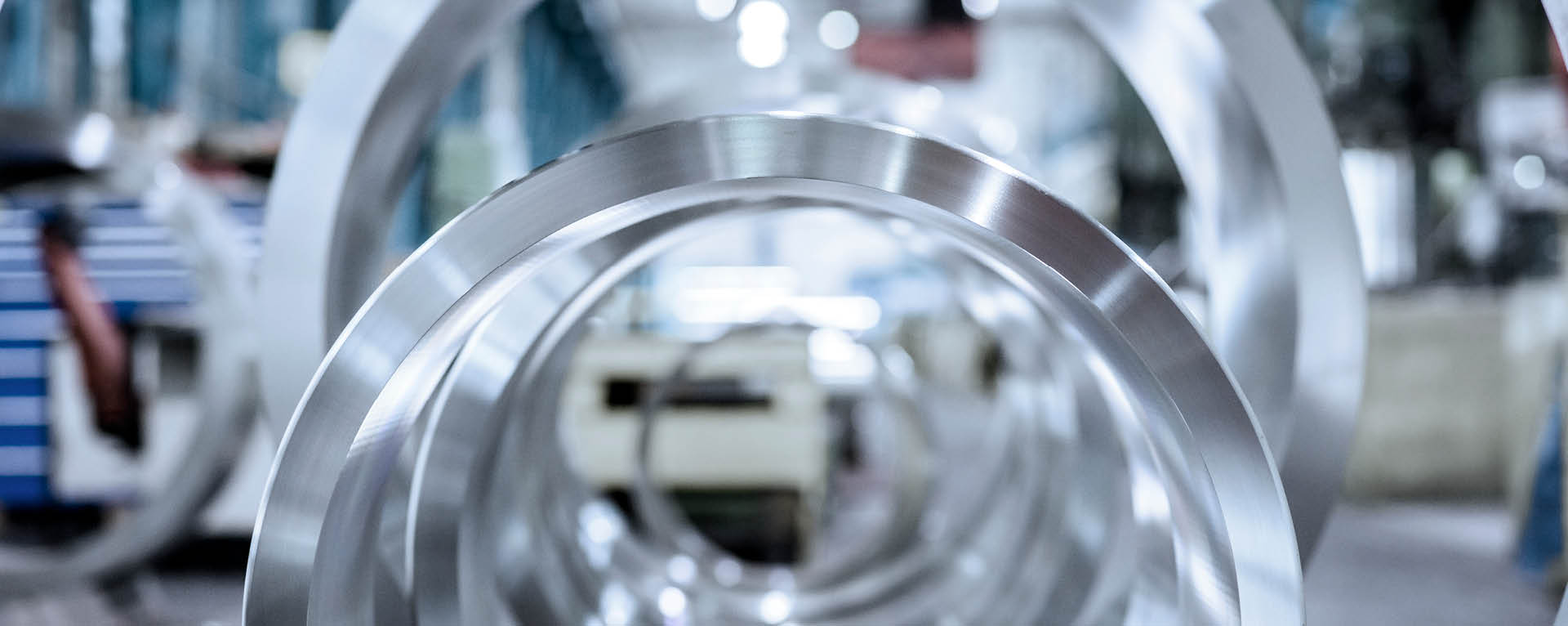

Retaining rings

For more than 100 years we have been developing and manufacturing retaining rings for turbo generators and other high-performance machines.

Our components made from austenitic steel P900 (material no. 1.3816, X8CrMnN18-18) combine exceptional strength and toughness with high resistance to stress corrosion cracking (SCC) — a decisive advantage for safe operation in power plant installations.

Key Properties

Nonmagnetic, high yield strength, very good cold and hot formability, low thermal expansion, resistant to stress corrosion cracking.

All rings are manufactured to order, special sizes available on request.

We manufacture the following dimensions:

Materials & Alloys

| Material | Material No. | Typical Application |

|---|---|---|

| P900 | 1.3816 | Standard retaining rings for turbo generators |

| Parameter | Range |

|---|---|

| Diameter | 430 – 2 200 mm |

| Weight | 15 – 4 300 kg |

From Ingot to Precision Retaining Rings — 9 Steps at a Glance

Our manufacturing begins with Green Steel ingots, melted from nearly 100% scrap in the electric arc furnace (EAF) — a key pillar of the GMH circularity strategy.

This is followed by a multi-stage quality process in which each step is designed for reproducibility, dimensional accuracy, and traceability.

Your contact for rotor retaining rings

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Electroslag Remelting (ESR) / Pressure Electroslag Remelting (PESR)

The steel is remelted in ESR units. This process minimizes inclusions and produces a homogeneous microstructure — the basis for retaining rings that withstand high loads.

Your contact for Electroslag Remelting (ESR) / Pressure Electroslag Remelting (PESR)

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Open-Die Forging

The remelted ingots are forged into bars and then into rings — with geometry optimized to customer specifications for ideal downstream processing

Your contact for Open-Die Forging

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Pre-Turning

The forged surface is removed, and dimensions are set for expansion.

Your contact for Pre-Turning

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Heat Treatment

The microstructure is homogenized by solution annealing in preparation for subsequent cold expansion.

Your contact for Heat Treatment

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Cold Expansion

The ring is cold-expanded at room temperature on an expansion press used exclusively for retaining-ring production, reaching the specified dimensions and the required strength level in a single step.

Your contact for Cold Expansion

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Stress-Relief Annealing

Residual stresses introduced during cold forming are removed by stress-relief annealing.

Your contact for Stress-Relief Annealing

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Finish Turning

The final dimensions and specified surface finish are achieved by finish turning.

Your contact for Finish Turning

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

100% Final Inspection

Every ring is tested for mechanical properties and internal defects according to the customer specification, results are documented, and the finished rings are delivered with full traceability.

Your contact for Final Inspection

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

Retaining Rings in Power Generation – Purpose, Advantages and Applications

- High rotational speeds up to 3,600 rpm require high-strength materials that safely absorb centrifugal forces

- Severe cyclic loading of components requires optimized designs

- Critical atmospheres inside the generator during operation increase the risk of stress corrosion cracking — targeted alloy composition safeguards operational reliability

- Precision surfaces facilitate maintenance, repair, and retrofit operations during overhauls

- Cost-effective: longer service life reduces operating costs and maintenance effort

- Product safety: best-in-class material properties for safe design and dimensioning

- Power Engineering: Securing the end windings on turbo generators and motors

What you can expect

Circular economy

We use almost 100% scrap in steel production, thereby enabling closed loops

Low CO2 production

use of 100% material from the electric arc furnace

Highly resilient steel

Highly resilient steel with high yield strength, very good cold and hot forming properties, low thermal expansion, non-magnetizability and resistance to stress corrosion cracking