Georgsmarienhütte, 05 February 2026

Green Power Steel for Hirschvogel

Georgsmarienhütte supplies low-emission steel for powertrain components – up to 95% lower CO2-emissions (Scopes 1 and 2)

Georgsmarienhütte GmbH, a company of GMH Gruppe, is supplying Hirschvogel Umformtechnik GmbH with low-emission Green Power Steel for powertrain applications, further strengthening their long-standing strategic partnership in the transformation toward climate-friendly industrial value chains.

With immediate effect, Hirschvogel is using an initially limited account Green Power Steel from Georgsmarienhütte to produce sophisticated formed components for powertrain systems. Produced in an electric arc furnace powered by 100 percent renewable energy, Green Power Steel reduces CO₂ emissions by up to 95 percent (Scope 1 and 2) compared with conventionally produced blast furnace steel. Even when accounting for Scope 3 emissions, the reduction still reaches up to 77) percent.

Since 2023, Georgsmarienhütte GmbH – the largest steel producer within GMH Gruppe – has been providing its customers with a Product Carbon Footprint (PCF) for all steel grades. The underlying methodology has been validated by TÜV SÜD and is applied to more than 1,000 steel variants, ensuring transparent, reliable and comparable CO₂ data across the product portfolio.

“Our partnership with Hirschvogel shows how low-emission steel can be successfully integrated into demanding industrial applications,” said Frank Agel, Member of the Management Board of Georgsmarienhütte GmbH. “With Green Power Steel, we are not only supplying a high-performance material but also making a concrete contribution to the decarbonization of automotive value chains. The unique combination of green electricity and TÜV-validated CO₂ accounting sets new standards in the steel industry.”

For Hirschvogel, the use of low-emission materials is a key lever in reducing product-related emissions. “Materials have so far accounted for the largest share of our products’ carbon footprint,” explained Dr. Christian Hinsel, responsible for Sustainability at the Hirschvogel Group. “By using low-emission steel from Georgsmarienhütte, we are taking an important step toward decarbonizing our components – and the vehicles in which they are used.”

The collaboration reflects a broader transformation within the automotive and supplier industries, driven by climate targets, regulatory requirements and rising customer expectations for low-emission products.

About GMH Gruppe

GMH Gruppe is a full-service provider of steel products, ranging from scrap-based steelmaking to ready-to-install components. It is one of Europe’s largest privately owned metal-processing companies. The group comprises 20 medium-sized production companies in the steel, forging and casting industries, serving customers in over 50 countries. With around 6,000 employees, GMH Gruppe generates annual revenues of approximately 2 billion euros.

GMH Gruppe is a pioneer in sustainable steel production and a member of the ‘German Association of Climate Protection Companies’. By recycling metal scrap, the company produces green steel and contributes to a circular economy. Electric arc furnaces at four sites reduce CO2 emissions by a factor of five compared to conventional blast furnaces – thus significantly lowering the carbon footprint for GMH customers worldwide. These include companies from the automotive, mechanical engineering, railway, energy, logistics, aerospace, agriculture and construction machinery sectors. GMH Gruppe is committed to achieving full climate-neutrality by 2039. www.gmh-gruppe.de

About Georgsmarienhütte GmbH

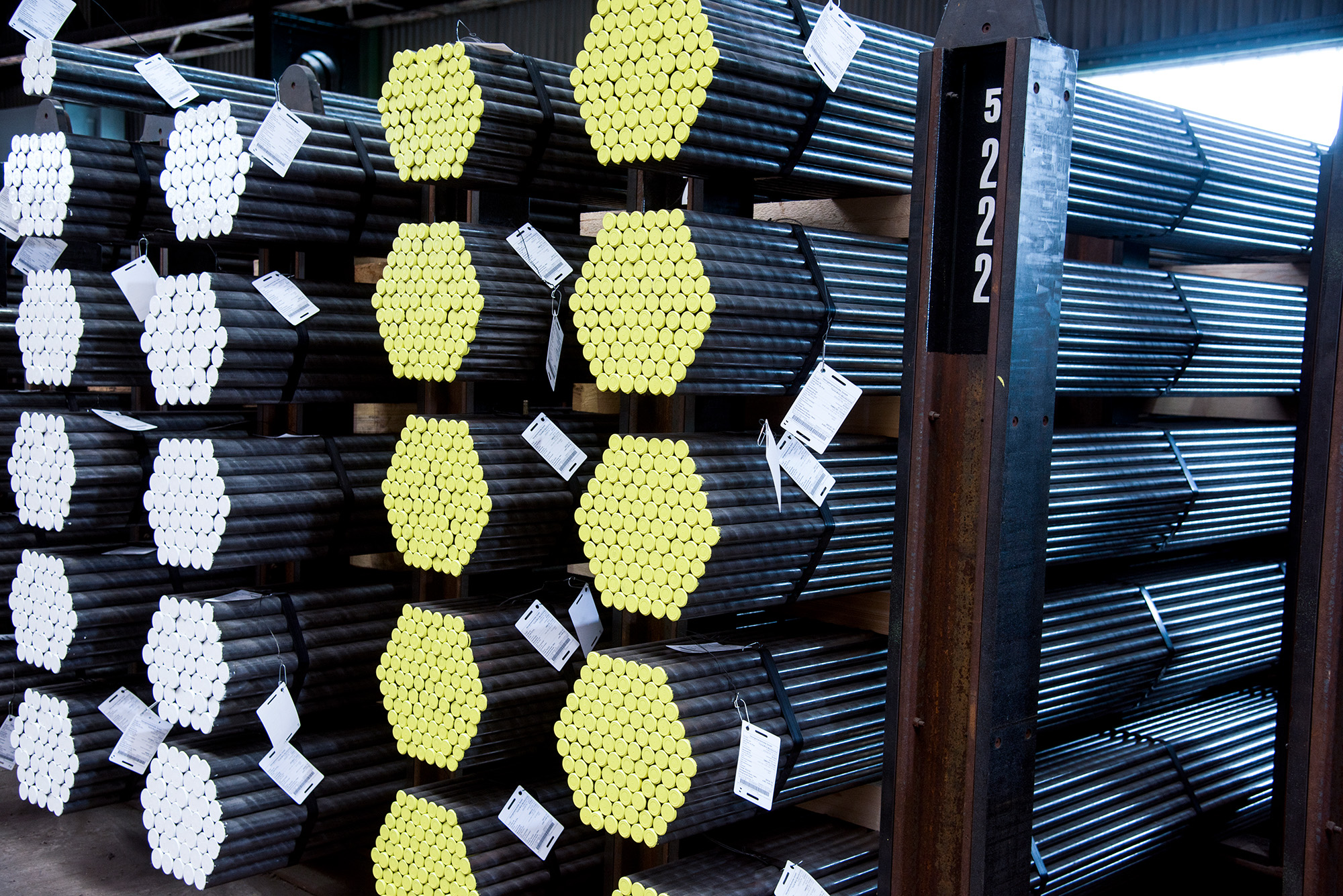

Georgsmarienhütte GmbH from Georgsmarienhütte in Lower Saxony is one of Europe’s leading suppliers of crude steel, bar steel and bright steel made from quality and engineering steels. The company also manufactures pre-processed and, in some cases, ready-to-install components. Georgsmarienhütte is already one of the most climate-friendly steel companies in Germany. With its comparatively low CO₂ value chain, in which scrap is melted in the electric arc furnace and recycled into new steel, it makes an important contribution to the circular economy and is a pioneer in sustainable steel production. The methodology used by Georgsmarienhütte to calculate the product carbon footprint (PCF) has been validated by TÜV SÜD and is now used for more than a thousand steel variants.

In addition to the automotive industry and its suppliers, customers are served in particular in mechanical and plant engineering and the energy industry. Steel from Georgsmarienhütte is used wherever the load is greatest, where power is generated or transmitted and safe and wear-resistant operation is important. www.gmh.de

For inquiries

GMH Gruppe

Luciana Filizzola

Director Sustainability and Communications