Schmiedewerke Gröditz GmbH

Schmiedewerke Gröditz GmbH:

Driving sustainable forging products

Schmiedewerke Gröditz GmbH is a leading manufacturer of open-die forgings, tool steel and rolled rings. The products are manufactured for various industries worldwide, e.g. energy machine construction, railroad technology and mechanical engineering. The focus on sustainability is reflected in our electric arc furnace, in which recycled scrap is efficiently melted into new steel. Electric steel production is a process in which new products are already being manufactured in an environmentally friendly manner in a closed material cycle. Choose Schmiedewerke Gröditz when it comes to quality, precision and a commitment to future-oriented steel production.

Sustainable, high-performance electric steel plant

In our electric steel plant, ingots based on steel scrap in various weights and formats are melted with low CO2 emissions. To refine our high-quality steels, we have an electro-slag remelting plant (ESR) at our disposal. In our steelworks, we produce 300 steel brands in over 2,000 analysis modifications. By minimizing waste and maximizing resource efficiency, we contribute to a cleaner planet and a circular economy.

Diverse excellence

in forging

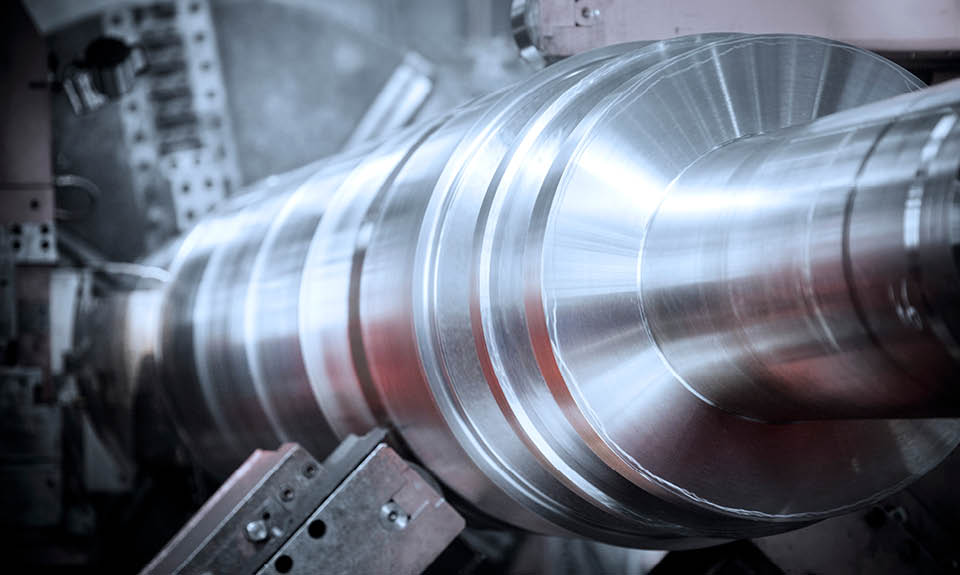

We produce forgings with complex contours for particularly demanding applications, e.g. turbine shafts for power plants. Among other things, we use two high-performance open-die forging presses for this purpose: a 27 MN and a 60 MN open-die forging press. In our ring rolling mill, we produce seamless rolled rings with rectangular or profiled cross-sections as well as wheel tires in more than 100 different steel grades.

Flexibility for our customers

We are able to realize individual wishes regarding the mechanical processing of rolled and forged products in-house. We are equipped with turning, milling, drilling and sawing machines for mechanical pre-machining and finishing. The company has heat treatment facilities for various technical requirements – from soft annealing and normalizing to oil and water quenching and tempering.

Discover the world of forging with factory tours at Schmiedewerke Gröditz GmbH!

Have you ever wondered how forged products are made from scrap metal? Take part in our factory tours for schools, universities and other educational institutions. Experience the entire process from melting the scrap to forging or ring rolling and the subsequent steps in mechanical processing. Immerse yourself in the exciting history of Schmiedewerke Gröditz and gain an insight into our diverse product range.

Your contacts

at Schmiedewerke Gröditz GmbH

Company:

Schmiedewerke Gröditz GmbH

Address:

Schmiedewerke Gröditz GmbH

Riesaer Straße 1

01609 Gröditz

Tel.: +49 (0) 35263 62-0

Fax: +49 (0) 35263 67944

E-Mail: info.swg@gmh-gruppe.de

Commercial register:

Amtsgericht Dresden HRB 18946

Sales tax identification number:

DE813144890

Management:

Hanka Snatkin

Stefan Zickuhr

Tax number:

209/119/00344

With green power ahead

We are pioneers in green steel – and we have big plans for the future. Join us! Together we are paving the way for a better world.

Shape a sustainable future with us

We are not only forging green steel, but also a green future.

As a visionary company, we not only set standards in steel production, but also in personnel management. We rely on the power of diversity and create a working environment that is characterized by openness, respect and appreciation. Our corporate culture is based on success and performance, entrepreneurship and GMH team spirit. Our employees enjoy a wide range of benefits – from 30 days of vacation to accident insurance.

Our advantages for your …

Finance

Financial stability is an important part of life. That’s why we offer a wide range of benefits to help you achieve your financial goals.

Health

Your health is important to us. That’s why we give you access to a comprehensive range of benefits for supporting your health and improving your wellbeing.

Work-life balance

We know how important it is to balance your work with your private life. We want you to be able to make the most of your time to achieve both your professional and personal goals.

Work environment and career development

Professional and personal development should be fun! We offer a whole range of benefits to help you fulfil your potential with us.

Safety

In the office, and especially in production, the health and safety of our employees is our top priority. So we invest in all kinds of mechanisms to keep you safe and protected in the workplace.

Come because you’ve come to the right place. Stay because you’ll never get bored with us.

Would you like to apprentice with us, like Janina and Kira?

Would you like a great start to your career, like Chantal and Ahmed?

Looking for a job with genuine prospects, like Christina and Sven?