Schmiedag GmbH

Schmiedag GmbH:

Excellence in Forged Components

Founded in 1824

Location: Hagen, North Rhine-Westphalia

Schmiedag GmbH specializes in the production of medium to large forged safety components up to almost 1 tonne in weight and up to 2m in length. We offer a wide range of products made from low to high-alloy steels, most of which are produced in-house and have low CO2 emissions. Our areas of application range from large engines, automotive & railroad technology, energy generation, oil, gas & mining to high-quality special applications, such as cable cars or special vehicles. We stand for the highest quality with 200 years of experience and rank among the market leaders in our industry in many areas. As a medium-sized company, we are characterized by a high degree of flexibility and customer proximity as well as a high level of engineering skill for tailor-made solutions. Our solutions range from forged blanks and mechanically pre-machined components to painted and fully ready-to-install products.

Our passion:

Innovative solutions made from green steel

In-house die and tool construction: everything from a single source

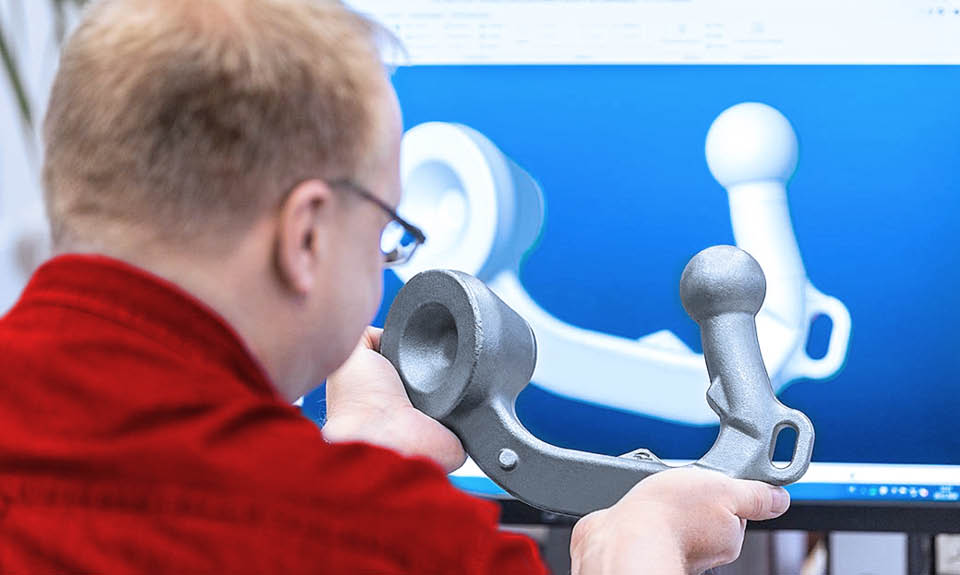

At Schmiedag GmbH, almost 100 % of forging dies are produced in-house – both in our own development and production facilities.

We use simulation processes to convert specific customer requirements into precision molds and tools and thus manufacture components with the highest accuracy.

Our manufacturing capabilities include the pre-machining of die blocks, machining on NC and CNC-controlled machines, including turning, milling and 5-axis milling centers.

With our in-house tool assembly and mold welding, we can fulfill customer requirements to the letter.”

Meeting the highest customer requirements

We translate specific customer requirements into precision molds and tools using simulation techniques to produce components with the highest accuracy. Our manufacturing capabilities include the pre-machining of die blocks, machining on NC and CNC controlled machines, including turning, milling and 5-axis milling centers. With our in-house tool assembly and mold welding capabilities, we can meet customer requirements to the letter.

Modern equipment meets 200 years of experience

We forge on forging hammers with 160 and 400 kNm as well as on presses with 31.5 and 45 MN with the highest level of precision.

Cost-minimizing efficiency and the use of materials characterize our drop forges, as does the special load-bearing capacity of the components thanks to favorable fiber courses.

We have been proving this for 200 years.

Our machinery also includes automatic feeding systems, preforming and handling equipment, industrial robots, heat treatment systems and extensive quality and measuring equipment using the latest technology.

In-house machining for ready-to-install components

We offer products along the entire value chain, from forged blanks to fully painted and ready-to-install components.

Our mechanical production includes machining centers, CNC lathes and state-of-the-art milling machines for pre-machining and finishing.

We also have a wide range of options for heat treatment, painting and assembly.”

Schmiedag GmbH

Company Video

Your contacts

at Schmiedag GmbH

Company:

Schmiedag GmbH

Address:

Schmiedag GmbH

Grüntaler Str. 11

D-58089 Hagen

Tel.: +49 (0) 2331 128-0

E-Mail: schmiedag@schmiedag.de

Commercial register:

Amtsgericht Hagen, HRB 9583

Sales tax identification number:

DE 290 957 893

Management:

Heinz Klenen

Tax number:

321/5746/0568

With green power ahead

We are pioneers in green steel – and we have big plans for the future. Join us! Together we are paving the way for a better world.

Shape a sustainable future with us

We are not only forging green steel, but also a green future.

As a visionary company, we not only set standards in steel production, but also in personnel management. We rely on the power of diversity and create a working environment that is characterized by openness, respect and appreciation. Our corporate culture is based on success and performance, entrepreneurship and GMH team spirit. Our employees enjoy a wide range of benefits – from 30 days of vacation to accident insurance.

Our advantages for your …

Finance

Financial stability is an important part of life. That’s why we offer a wide range of benefits to help you achieve your financial goals.

Health

Your health is important to us. That’s why we give you access to a comprehensive range of benefits for supporting your health and improving your wellbeing.

Work-life balance

We know how important it is to balance your work with your private life. We want you to be able to make the most of your time to achieve both your professional and personal goals.

Work environment and career development

Professional and personal development should be fun! We offer a whole range of benefits to help you fulfil your potential with us.

Safety

In the office, and especially in production, the health and safety of our employees is our top priority. So we invest in all kinds of mechanisms to keep you safe and protected in the workplace.

Come because you’ve come to the right place. Stay because you’ll never get bored with us.

Would you like to apprentice with us, like Janina and Kira?

Would you like a great start to your career, like Chantal and Ahmed?

Looking for a job with genuine prospects, like Christina and Sven?