Producing hot-rolled special profiles in customized geometries and steel grades is our core competence. These products save you time and money, because no further processing and finishing is needed. Our made-to-order shapes and custom steel properties also reduce the weight of your end products.They improve dimensional accuracy in general and enhance the mechanical properties of the components they are used in. Last but not least, our special profiles provide surfaces that meet the most exacting quality requirements.

Welcome to Mannstaedt GmbH & Mannstaedt Inc. !

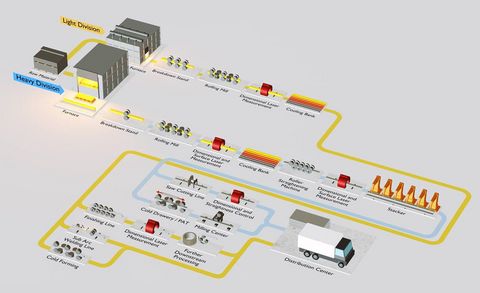

We are a world leader in hot-rolled steel special profiles. Our expertise is born from decades of experience in many fields: engineering, metallurgy, roll design, hot rolling and further processing. Our steel profiles make the impossible possible.

Plan your journeyYour Mannstaedt Inc. and Mannstaedt GmbH contacts

Ingo Offermanns

Sales Director Profiles- Phone: +49 2241 84-2137

- Email: ingo.offermanns@gmh-gruppe.de

Erk Lehmler

Head of Sales Material Handling- Phone: +49 2241 84-2119

- Email: erk.lehmler@gmh-gruppe.de

Andreas Otto

Head of Sales Automotive, Construction, GE- Phone: +49 2241 84-2132

- Email: andreas.otto@gmh-gruppe.de

Marco Esquivel

President & Sales Director, Americas- Mannstaedt, Inc.

- 3350 Riverwood Pkwy, Suite 1900

- Atlanta, GA 30339

- USA

- Phone: +1 404 992-3991

- Email: m.esquivel@mannstaedtinc.com

Our Products

Steel moulded to your individual needs

Special steel profiles

Developing solutions for any requirement

We always meet our customers’ requirements, whether they are looking for special material properties or have particular expectations in terms of straightness, drilling, surface quality, or the lengths of their bars or pieces. No other manufacturer of special profiles can rival the variety of products and materials we offer.

Committed to more than just steel

Taking responsibility – not just for ourselves, but also for others – is one of our top priorities. This attitude shapes the way we think and everything we do. Preserving the environment and climate as well as protecting our staff and the people around us are key concerns for us as a company. That’s why we follow standards that go above and beyond our certifications.

Our location movie

Site management

Thomas Leven

Plant Director Mannstaedt GmbH | Managing Director

Sebastian Ahrens

Commercial Director Mannstaedt GmbH | Managing DirectorDownloads

| File name | File size | |

|---|---|---|

| Mannstaedt GmbH Special Profiles | 1.001,41 KB | Download |

| Mannstaedt GmbH Special profiles for mining | 366,19 KB | Download |

| Mannstaedt GmbH Special profiles for railway | 768,44 KB | Download |

| Mannstaedt GmbH Special profiles for the materials handling industry | 485,39 KB | Download |

| Mannstaedt GmbH Standard Sheet pile locking bar profiles | 586,92 KB | Download |

| File name | File size | |

|---|---|---|

| Mannstaedt GmbH DoP hot rolled achor channel in stainless steel | 3,43 MB | Download |

| Mannstaedt GmbH DoP hot rolled sections for special applications in steel grade S235JR | 3,61 MB | Download |

| Mannstaedt GmbH DoP hot rolled sections for special applications in steel grade S275 | 9,29 MB | Download |

| Mannstaedt GmbH DoP hot rolled sections for special applications in steel grade S355 | 9,55 MB | Download |

| Mannstaedt GmbH DoP hot rolled zees with round edges in steel grade S235JR | 3,49 MB | Download |

Your contact for Site Communication

Contact

Monika Hansen

Communications Mannstaedt GmbH- Mannstaedt GmbH

- Mendener Straße 51

- 53840 Troisdorf

- Phone: +49 2241 84 - 2001

- Email: Monika.Hansen@gmh-gruppe.de