High-strength steels with high energy efficiency

High-strength steels with high energy efficiency

New materials for the automotive industry

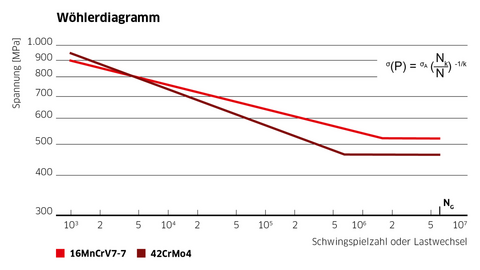

The introduction of the EEG (German Renewable Energy Sources Act) surcharge has significantly increased the pressure for the industry to become more energy-efficient. Working closely with our customers in the automotive industry, we have developed two new steels that will play a significant role in saving energy. In turn, these have provided a platform on which we have been able to come up with new concepts for energy-efficient, cost-effective process routes.