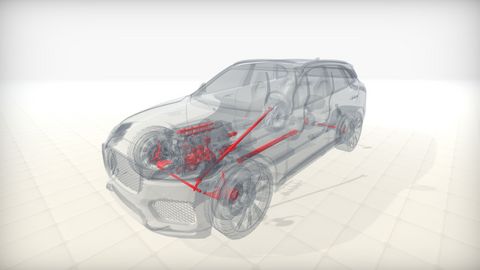

We make things lighter

For powertrain and chassis/suspension components in passenger and commercial vehicles, lightweight engineering has become a topic of continuously growing significance. GMH Gruppe experts have joined forces with other specialists in the “Lightweight Forging Initiative”, a research project that has generated no less than 1,917 ideas, with a total weight reduction potential of 358 kg. Our ultra-light components are already in service today in numerous applications, including, for example, our innovative 46MnVS5 grade – a high-strength steel which makes crack piston rods 10% lighter.