Group-wide recycling

Group-wide recycling

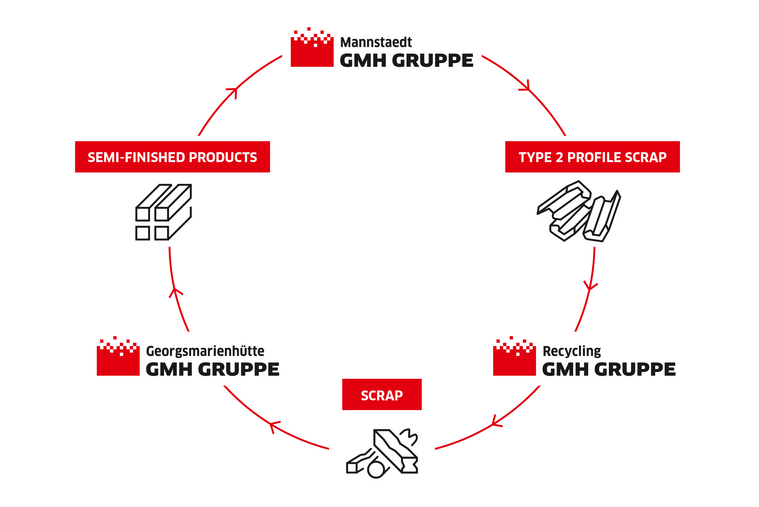

Closed cycle

Scrap is the basis of GMH Gruppe’s steel production: Our steel is melted from 100% scrap. This makes our raw material recycling the pivotal point of our sustainable circular economy – not only at the individual location, but also across locations within GMH Gruppe, as the example of Mannstaedt shows.