Adding value sustainably

Adding value sustainably

Good for the environment and for the customers

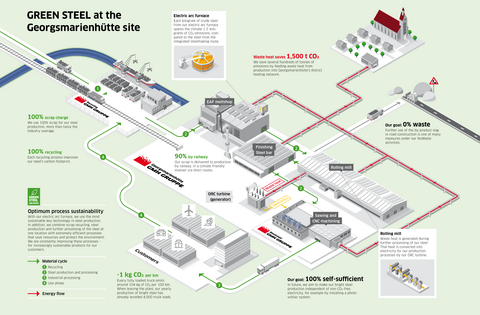

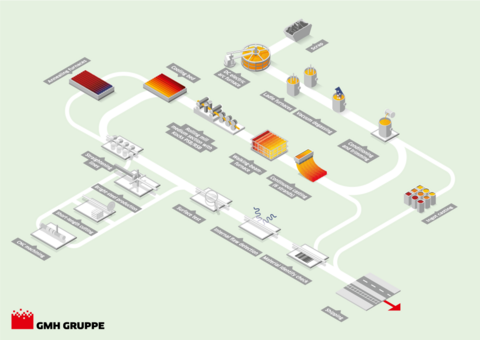

Whether a customised alloy concept, high-quality steel bars, precisely peeled bright steel sawn exactly as specified or CNC components delivered just in time and ready for installation: Excellent steel is sold in various forms along the complete value chain. Compared to many other manufacturers, GMH Gruppe produces its steel in an extremely sustainable manner along the entire value chain, thanks, among others, to maximum synergies within the Georgsmarienhütte location. This provides many benefits for the environment and for our customers – the five most important ones being: